Diesel Fuel Tank Cleaning Video

What is Diesel Fuel “ALGAE”?

Algae are a life form found in water, similar to algae growing in an aquarium. However, for years, people have been referring to tank sludge and to the jelly, slime and other contaminants found in fuel filters as “algae”. The colloquialism “diesel fuel algae” is widely used and understood. However, there is no relationship between the “algae” growing in your aquarium and the sludge “growing” (forming) in your fuel tank and showing up on your filter elements.

There are three basic areas of concern in fuels and oil. They are: 1. Water 2. In-Organic Debris (sand, dust, rust, etc.) and 3. Organic Debris (fuel breakdown products and waste products of fuel deterioration and re-polymerization). The organic debris represents more than 90% of all the contaminants found in fuels and oil. It is this organic debris, the sludgy, slimy, acidic material that people refer to as “diesel fuel algae”. It could also be called polymer, tar or wax and asphalt!

In South America, people refer to the “Algae” as “mud”. In gasoline, the organic fuel breakdown products are often referred to as gum, varnish, or lacquer. Taken literally these words could be confusing too.

What is Diesel Fuel?

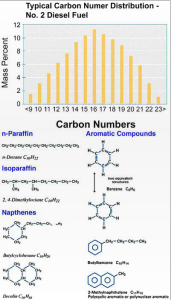

Diesel fuel is a very complex mixture of thousands of individual compounds with carbon numbers between 9 and 23 (number of carbon atoms per hydrocarbon* molecule) Most of these compounds are members of the paraffinic, naphthenic or aromatic class of hydrocarbons (HC). These three classes have different chemical and physical properties. The different relative proportions of the three classes is one of the factors that make one diesel fuel different from another. It influences fuel properties and affects its performance.

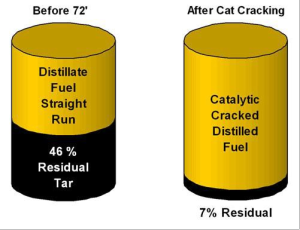

Up until about 15-20 years ago, refineries used only about 50% of a barrel of crude oil to make distillates such as gasoline, jet fuel and diesel. The remainder of the barrel of crude oil went to “residual oil”. Today, as a result of different refining techniques and additive packages, the refinery uses 90% or more of the same barrel of crude, which clearly has consequences for fuel stability.

*Hydrocarbons are organic compounds composed entirely of carbon and hydrogen divided in four major classes: paraffins, naphthenes, olefins, and aromatics. These classes share common structural features but differ in size, (number of carbon atoms per molecule) and/or geometry. While hydrogen and carbon are the predominant elements in crude oil, small amounts of sulfur, nitrogen and oxygen are also present and referred to as hetero-atoms (other-atoms). Compounds containing hetero-atoms are non-hydrocarbons. Typical non-hydrocarbons found in diesel are dibenzothiophene and carbazole, which play a large role in determining certain fuel properties.

More than 90% of the debris on filter elements and the sludge in our storage tanks is organic material, fuel and oil breakdown residue. In most cases, this debris is acidic and not good for your engine. It causes corrosion in injectors, pumps and storage tanks.

The solids that form as the result of the inherent instability of the fuel and the natural process of degradation will accumulate in the bottom of your tank. The sludge will form a coating or bio-film on the walls and baffles of the tank, plug your filters and impact combustion efficiency. Eventually it will clog fuel lines and ruin your equipment.

What is the “stuff” that clogs my filters?

Filter plugging can have several causes. For example, low temperatures can cause wax crystallization, which can lead to filter plugging. An example would be using summer diesel in cold weather. Wax or paraffin is part of the diesel fuel. A Winter Fuel Catalyst with an Anti-Gel additive is the answer to that problem.

Chemical incompatibility may cause dramatic filter plugging. This may happen when fuels with incompatible additive packages are mixed.

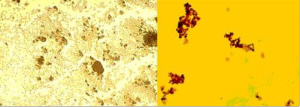

Contaminant build up resulting from excessive microbial growth and bio-degradation of fuel can cause filter plugging. Micro-organisms, bacteria and enzyme activity, fungus, yeast and mold cause fuel degradation and the formation of waste products. The process is similar to milk turning into cottage cheese, a different form of milk. Of all the microbial debris and waste products in the tank only about .01% is bugs. Even though microbes may cause and accelerate the process of fuel degradation, it should be clear that the waste products clogging your filter are not the microbes but fuel components which have formed solids.

Frequently, the application of a biocide aggravates the situation and turns bio-film into solids, creating a real fuel filter nightmare. Bio film develops throughout the entire fuel system. It grows in the water fuel interface and on the walls, baffles, and bottoms of storage tanks. An unlucky end user may be filling up his tank and getting this debris delivered as a part of his fuel, for the same price as the fuel.

Poor thermal fuel stability can plug filters. Fuel will form particulates (solids) when exposed to pumps and the hot surfaces and pressure of the fuel injection system. This will result in an increase in asphaltene agglomerations, polymerization and a dramatic loss of combustion efficiency.

Fuel systems, in general, are designed to return a significant proportion of the fuel, not used for combustion, back to the tank. This return fuel is very hot and will promote polymerization and fuel breakdown. Eventually, more and more solids from the tank will reach the filter and over time, plug the filter. These problems continuously occur in commercially operated engines, such as trucks, heavy equipment, shipping, and power generation, but will also appear in recreational boats, RV’s and all types of fuel storage tanks.

Truck engines are used continuously and, in most cases, the tanks “appear to be clean”. However, a 2- micron filter element does not last very long, in general 15,000 miles or less. It should be 30,000 miles or more. In the marine industry 400 hours is in many instances SOP while filters should easily last 1,000 hours or more.

The size of the largest diesel fuel molecule still within specs is approx. 30 Angstrom (that equals approx 0,003 of a micron). Compared to a 10-micron opening in a filter element, one can have 3,333 of these particular molecules passing through the opening side by side. E.g. comparing the size of a baseball to two and a half football fields.

Short filter life is quite remarkable realizing how “thin” diesel fuel actually is and knowing how clean the tanks on most trucks “appear” to be.

Short filter life is symptomatic of polymerization, increase in the size of the fuel droplet, agglomeration of asphaltenes and the formation solids in fuel systems. The consequences are carbon build up in engines and exhaust systems, higher fuel consumption and excessive smoke.

Can diesel fuel plug your filters?

Yes, it can. The stuff that clogs your filters is actually fuel in some way, shape or form. In excess of 90% of this organic debris are fuel breakdown products. It is not sand, dust, stones, rust or in-organic matter that blocks your filter.

The inorganic material like sand, dust and other particles will not cause your filters to clog. In fact, a lot of sand in a fuel filter would act as extra filtration. The pores between the sand particles are much larger than the pores in a standard fuel filter element. Sand filters are commonly used to filter water. A hair is approximately 80 micron and fuel filter elements range all the way from 30 micron for a prefilter to 2 micron in a fine filter.

How does fuel stability affect the user?

Fuel stability is a serious concern for the diesel fuel user.

The chemistry of diesel fuel instability involves the chemical conversion of precursors to species of higher molecular weight with limited solubility. The conversion process often involves oxidation of the precursors. Fuel solvency plays a role, since the development of insolubles is always a function of both the presence of higher molecular weight species and the fuel capacity to dissolve them.

We all realize that fuel is an unstable, organic liquid that goes “bad”. Your vendor will always sell you the highest fuel quality possible. However, due to a variety of circumstances fuel may have “aged”, oxidized and/or contain water. It may have been contaminated before it was delivered to you or to your vendor.

Fuel has to travel from the refinery to the end user destination. It is pumped through pipelines, barged, trucked and stored in tank farms. Diurnal changes in temperature and exposure to the atmosphere will cause condensation and water in storage systems. None of this will help improve fuel quality.

When your fuel is finally used, it is exposed to the heat and pressure of engine injection systems, centrifuges, pumps, heaters causing an increase in asphaltene agglomerations, which negatively impacts combustion efficiency and emissions.

What is bad fuel?

Fuel is made to certain ASTM specifications. When it does not meet these specs, we could refer to it as “bad fuel”. However, we tend to refer to fuel as “bad fuel” when we see symptoms such as: -dark hazy fuel, -filter plugging. -sludge build up in tanks, -poor engine performance, -excessive smoke & emissions, -etc. We refer to fuel as “good fuel”, when it is clear and bright. Or rather in that case, no reference is made at all to our fuel. We simply use it and take fuel quality and peak engine performance for granted. Bad fuel is fuel that does not meet ASTM specifications.

What does Optimal Fuel Quality mean for me?

Optimal Fuel Quality means Peak Engine Performance. New engines will retain maximum engine efficiency much longer using good quality fuel. Polished and treated fuel extends the life of both old and new engines.

Polishing and Fuel Conditioning Technology Optimizes Fuel Quality and eliminates the buildup of organic solids, tank sludge, acid formation and clogged filters. It enhances combustion by reducing the size of the fuel droplet, eliminating carbon build up and reduces harmful exhaust.

The implementation of Polishing and Fuel Conditioning Technology, lowers operating cost, brings equipment in compliance with the Clean Air Act, and deals with environmental concerns about smoke, particulate and oil sheen on the water.

Is “Dark Fuel” the same as “Bad Fuel” and can I still use it?

This is a question many of us have asked more than once. And what we really want to know is: “Will the stuff damage my engines?” Engines are expensive, ruining an engine is costly and operating an engine on “bad fuel” is not wise.

We all know that most engine failures start in the fuel tank. When all mechanical parts are in good operating condition, the cooling and lube systems are working, the lube oil is clean and there is a sufficient supply of clean air getting to the combustion chamber, a diesel engine or turbine could almost run forever. The only limiting factor is Fuel Quality. Dark fuel is symptomatic of poor quality and even though, in most cases, it can be used, fuel in this condition will provide poor combustion and filtration problems.

“Dark fuel” is in general indicative of oxidation and that the process of fuel degradation is in a far advanced stage. Hazy fuel is indicative of water emulsified in the fuel. In general, dark hazy fuel will not damage your engine. It indicates however, poor fuel quality, which will definitely not provide you with peak engine performance.

Using less than optimal fuel quality negatively impacts engine efficiency and accelerates the process that makes new engines old.

Diesel fuel can range from colorless, to amber or light brown color, depending on the crude oil and the refinery process used to produce it. In addition, dyes may be added to change the fuel color for tax identification purposes.

In time, stored fuel will darken due to oxidation, repolymerization and agglomeration of certain components. The darkening is accompanied by the formation of sediment that plugs filters and causes poor combustion. Fuel & Oil vendors suggest that if diesel fuel is stored for emergency use, it should be replaced with fresh fuel within a year, unless special precautions or remedial actions are taken.

The University of Idaho conducted tests on the life expectancy of fuels to determine the timeline on degradation of stored #2 diesel. The results indicated 26% degradation after 28 days of storage. Disposing of Fuel and purchasing New Fuel is a very expensive proposition. Many larger companies, government institutions, hospitals, etc. have the dumping of fuel and the purchasing of new fuel as standard and accepted practice.

The implementation of Polishing and Fuel Conditioning Technology eliminates these costly, wasteful, and environmentally unfriendly dumping practices. Polishing and Fuel Conditioning will preserve fuel integrity almost indefinitely and can help you put in place good housekeeping measures along with a quality fuel-monitoring program.

How does my engine negatively impact fuel quality?

A diesel engine uses only some of the fuel it pulls from the tank. All of that fuel goes to the high-pressure fuel pump and to the injectors operating under enormous pressure and high temperatures.

The surplus fuel the engine is not using goes back to the tank. This fuel is continuously re-circulated and exposed to extreme pressure and heat, which results in the agglomeration of asphaltenes, the high carbon content, and heavy end fuel molecules. It leads to the formation of larger and larger clusters and solids, which are very difficult to completely combust. These solids may grow so large that they will not pass through the filter element and become part of the polymer and sludge build up plugging the filter.

In addition, the hot fuel coming back to the tank will raise the fuel temperature in the tank, cause condensation and contribute to microbial contamination, fuel break down, bio-fouling and the buildup of sludge and acid.

Large fuel droplets and high asphaltene concentrations require more time, more energy and higher temperatures to combust than is available in engines during the combustion cycle and before the exhaust valve opens.

Any device in the fuel system exposing the fuel to stress (heat and pressure) such as pumps, heaters, or centrifuges will increase the formation of asphaltenes and negatively impact combustion.

Isn’t my filter supposed to keep my fuel system clean?

Well, filtration simply cannot and will not do that. At best, filters, separators and centrifuges remove debris suspended in the fuel before the fuel reaches the engine. Stopping, preventing or reversing the process of fuel breakdown is a completely different matter that can be addressed and resolved with Polishing and Fuel Conditioning. It is not very likely that filtration, (either the filter on the engine, or an external filtration system) will remove the sludge coating from the walls and baffles of your storage tank and the use of biocides will almost always aggravate the situation. Filtration has no effect on fuel break down processes whatsoever.

Filters are primarily designed to remove in-organic debris from the fluid stream and, as we have seen, they become clogged with organic debris, resulting from fuel degradation. The water separator is designed to remove free-water. However, a separator, filter combination or centrifuge cannot remove emulsified water. Free water in fuel can simply be removed from the fuel stream with the use of a water separator. Several well-known and very efficient combination Filter/Water separator devices are on the market. They are essential in any diesel engine application.

Simple in-organic debris, dust, sand, rust, etc. can easily be removed from the fuel stream with a filter. That is what the filter was made for. This in-organic material will be trapped in the filter without clogging it. Most of the debris we see on the filter elements (the stuff that plugs our filters) is the result of the fuel having begun to form solids.

What are the problems related to long-term fuel storage?

Temperature, humidity and condensation are very important factors in managing fuel integrity. The presence of free water provides the medium for microbiological growth that results in the formation of slime and acids causing corrosion of metal surfaces such as storage tanks, pumps, injectors, etc.

Other key factors leading to fuel deterioration, polymerization, and stratification in storage tanks are chemical incompatibility and stress caused by heat and pressure of pumps, centrifuges, and heaters. Since most diesel engines return considerable amounts of fuel back to the tank, it is easy to see that the engine itself contributes to fuel deterioration.

How do we protect stored fuel?

Good housekeeping and purchasing clean, dry fuel from a reputable supplier are definitely step one.

In applications, such as emergency power generation, it is recommended that an in-line fuel re- circulation/filtration system be installed or the use of a portable Polishing and Fuel Conditioning Treatment System be used about twice a year.

These commercial high capacity in-line systems typically have the following basic components: a pump, a Fuel Conditioner, a filter/water separator, a water block or fine filter, a timer, and an electronically controlled monitoring systems with alarms.

It is recommended to start out the program by implementing a Fuel Catalyst to stabilize the fuel in the tank. Additional components in the Fuel Catalyst are corrosion inhibitors and lubricity enhancers to not only preserve fuel integrity, but also to protect your engine equipment.

Traditionally, biocides and filtration were the only treatment available. In many cases, we have seen that this regime caused more harm than good. The use of an adequate fuel quality management program and service, regular fuel testing to monitor fuel integrity are an absolute necessity and will save money. Periodically adding stabilizer is another common practice used for example with nuclear power plants, which all have back-up diesel powered generators.

Installing a dedicated, in-line, Fuel Quality Management system that automatically operates and purifies the fuel is becoming a rapidly accepted standard maintenance for hospitals, computer and telecommunications companies.

We also need to remove from our storage tanks any water and monitor fuel quality for microbial contamination on regular intervals. Since most tanks do not have a water sump or a sloping bottom that can be drained at the lowest point, we may need to find other ways to remove water from the fuel supply. To remove water from fuel tanks we recommend the use of a Tank Cleaning/Fuel Conditioning and Filtration System that includes a “Water Eliminator”.

The “Water Eliminator” is typically a small nylon or a larger stainless steel cylinder, containing a special polymer. The polymer will absorb the water (not the fuel) for easy removal. The Portable Polishing and Fuel Conditioning System is a compact mobile tank cleaning system used to remove water from the tank bottom and works as a fuel dialysis and treatment polishing system.

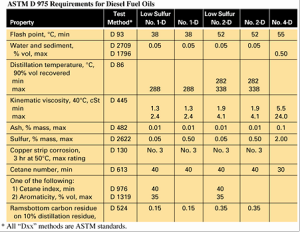

Does low sulfur diesel fuel have enough lubricity?

Generally – Yes. Even though the process used to lower the sulfur in diesel can also remove some of the components that give the fuel its lubricity. We recommend the use of a Fuel Catalyst with lubricity enhancer, as needed, to raise the lubricity to an acceptable level and protect injection systems of the engine.